US-Based, ISO-13485:2016 Certified, and FDA-Registered.

Owner-operated with a passion for manufacturing - RevZero is the optimal size to meet your contract manufacturing needs - big enough to maintain a robust quality system and attract great talent while small enough to remain innovative and responsive, avoiding the bureaucratic costs of larger companies.

Founded in 2007, our name stems from the [Rev. 0] commonly written on the first draft of an engineering print, and highlights our commitment to serving product designers early in the design process. We specialize in precision machining and design-for-manufacturability.

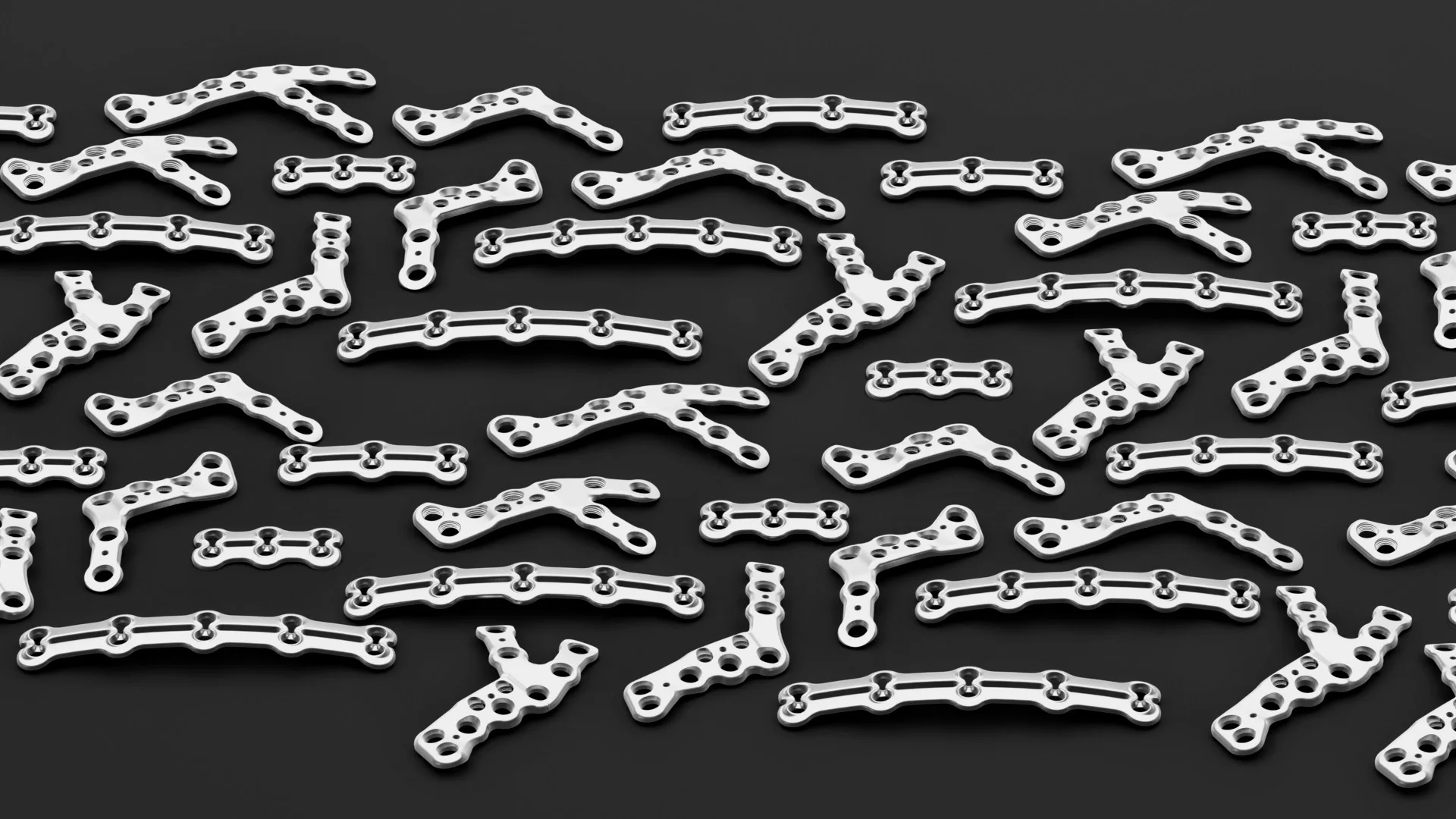

PRODUCT FOCUS

SPECIALIZED IN COMPLEX PLATES, SCREWS, SPACERS, and Minimally Invasive Medical Devices

Exclusive Focus on Medical Device Manufacturing

We Understand Your Needs and Requirements

EXTREMITIES/TRAUMA

Plates & Screws for Foot & Ankle, Distal Radius, Ulnar, Humeral, Tibia, Clavicle, Olecranon, Calcaneus, and Metatarsal, plus Solid and Cannulated Screws.

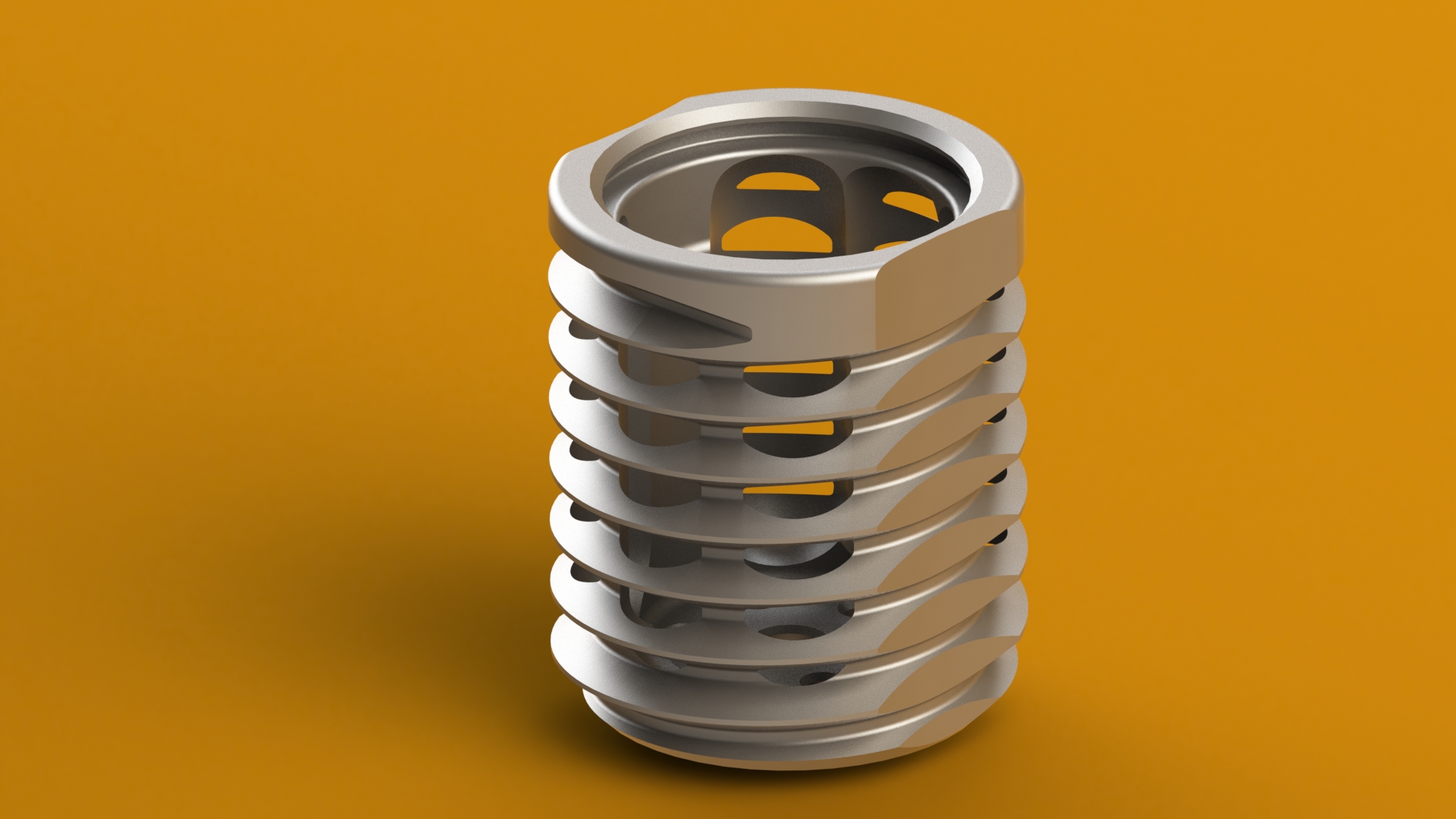

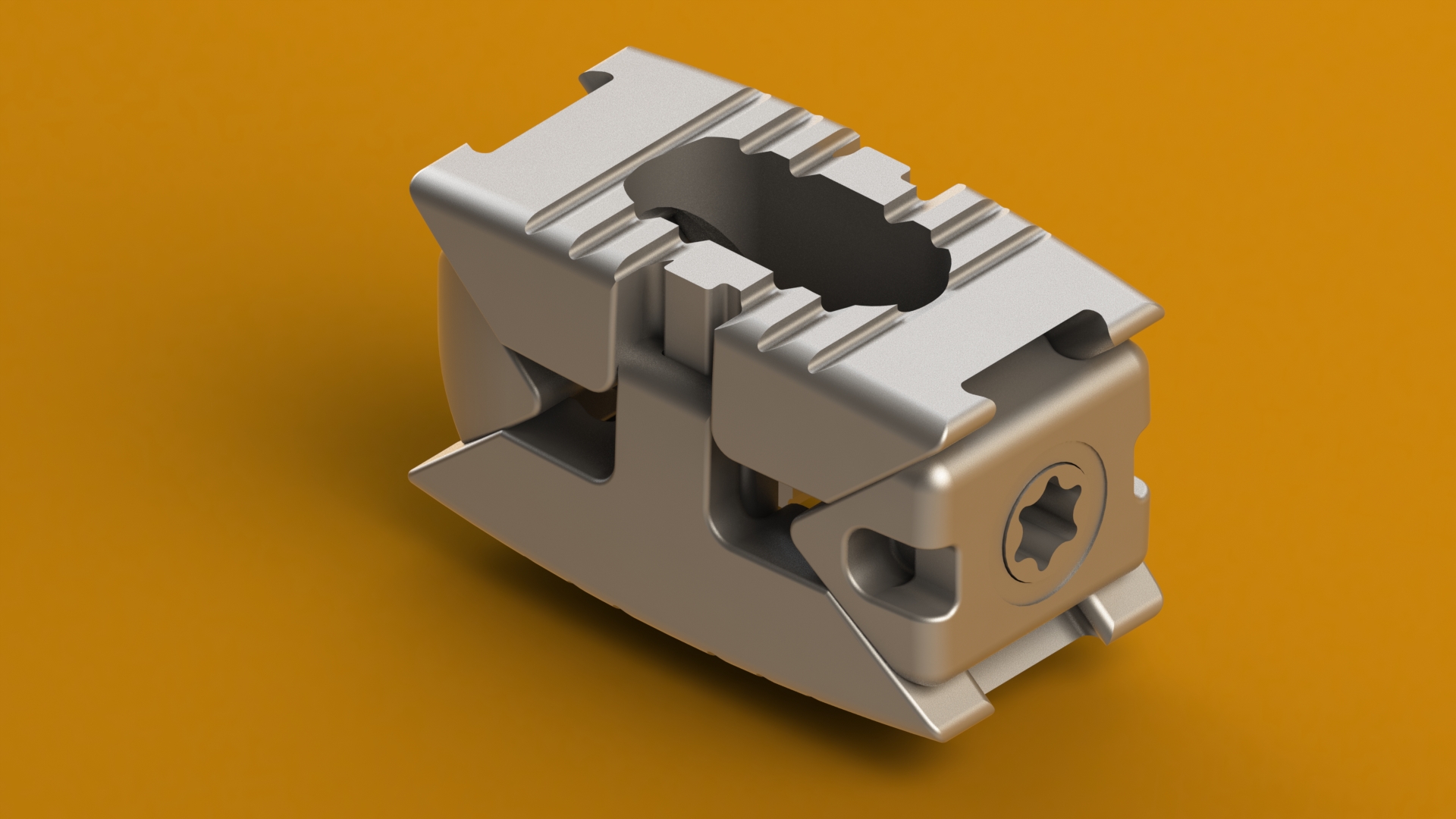

SPINAL

Expandable Interbody Spacers, Spinal Plates, Screws, and Rods, Anterior, Posterior, and Lateral Fusion, Sacroiliac Joint Compression Screws, Pedicle Screws, etc.

Capabilities

SWISS LATHE

PRECISION TURNING

Multiple Star, Citizen, and Tsugami Swiss Lathes from 12mm to 32mm.

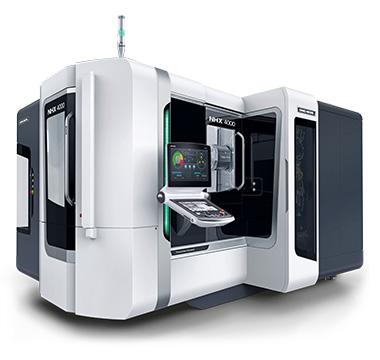

CNC MILLING

AUTOMATED MULTI-AXIS

CNC cells blend milling and turning with machines from Willemin-Macodel, Mori Seiki, Haas, and Mazak. All machines are optimized for 24/7 production.

ELECTRICAL DISCHARGE

EDM WIRE AND DRILL

Agie & Fanuc EDMs incorporate 0.003"-0.010" wire, 3R tooling, and submersible rotary tables. Current EDM hole drilling machines produce holes down to 0.004".

FINISHING

Centrifugal Barrel Finishing, Otec Tumblers, Crest Ultrasonic Cleaning and Citric Passivation Consoles. Additional services include; heat-treating, bead-blasting, electro-polishing, plating, anodizing, and grinding.

LASER MARKING

FOBA 20-Watt laser system creates UDI compliant clean and precise markings at 600+ dpi.

ENGINEERING SUPPORT

Full CAD review includes DFM & DFI analysis and potential PPAP requirements. SolidWorks, Partmaker, Mastercam, WinCNC, QC Calc, PC-DMIS, and 3D printing capabilities.

Materials: 316LVM, Titanium 6Al-4V ELI, Cobalt-Chrome, PEEK, Heat-treatable SS, Aluminum, Lexan, etc.

Unique Capabilities: Sub-micron surface finishes, complex assemblies, rapid and flexible development process, advanced high-speed multi-axis milling.